51

Build Threads / Re: Car Hauler Trailer Build

« on: October 01, 2017, 02:13:37 PM »No removeable fenders?

No not on this one. To be honest I've had several trailers of various sizes and never once wished for removable fenders.

|

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to. 51

Build Threads / Re: Car Hauler Trailer Build« on: October 01, 2017, 02:13:37 PM »No removeable fenders? No not on this one. To be honest I've had several trailers of various sizes and never once wished for removable fenders. 52

Build Threads / Re: Car Hauler Trailer Build« on: October 01, 2017, 11:45:31 AM »

Got the cross member tacked in place where I will be mounting my tongue jack

Also got both fender tacked in place. This is just the first side that I did. I had to space the fender out 1.5" from the frame rail to properly cover the tires. I'll put two vertical pieces of angle iron on the outside of the frame rail to support it.

53

Build Threads / Re: Car Hauler Trailer Build« on: October 01, 2017, 08:04:06 AM »Are you going to weld flat bar on outside of all the stake pockets? Yeah, ti's true, it would be handy. Perhaps I'll do that today. You can actually see one of the pieces of flat bar I have in the picture of the stake pockets! Since it's not the same width as the stake pockets, I wonder if it would be better to keep it flush with the top of the stake pockets, or in the middle, or flush with the bottom? 54

Build Threads / Re: Car Hauler Trailer Build« on: September 30, 2017, 07:43:44 PM »Are you going to weld flat bar on outside of all the stake pockets? I'm not sure. I might. If I do it will be just over the 3 pockets in front of the the fenders. I do have some 1.5" x 1/4" I could use. 55

Build Threads / Re: Car Hauler Trailer Build« on: September 30, 2017, 06:54:45 PM »

Found some 3/8" flat bar in the scrap pile at the farm, so decided to use that. I think it will be ok. I left a space of 24" in the middle, as I can't image loading something that has a track narrower than 2 feet !

Cut some spacers at 1"  Cut some length of bar to weld onto the spacers  And here they are welded on  Here's a shot of some of the stake pockets welded on

56

Build Threads / Re: Car Hauler Trailer Build« on: September 29, 2017, 10:06:49 AM »Stake pockets welded on! Thinking about the best thing to go across the end of the trailer for the ramps to hook into. Perhaps flat bar with spacers every couple feet? Perhaps 1" angle that is 3/16" thick? I'm thinking this might be the easiest. Might drill a hole every foot or two so water can drain as well. 57

Build Threads / Re: Car Hauler Trailer Build« on: September 28, 2017, 09:16:27 PM »

Stake pockets welded on! Thinking about the best thing to go across the end of the trailer for the ramps to hook into. Perhaps flat bar with spacers every couple feet? Perhaps 1" angle that is 3/16" thick?

58

Medical Corner / Re: Recognize a Stroke« on: September 26, 2017, 08:22:11 PM »

When we go to stroke calls, we do those 3 tests amongst a few others. One good thing to do is get the person to close their eyes when raising their arms. The reason being, that if they are watching themselves raise their arms they may inadvertently try to compensate for one arm if it's not raising like the other and might make your "test" results harder to verify.

One way we tell people to remember the checks is to thing of F.A.S.T (it's even written on our ambulances) Face - any drooping? Arms - raise unevenly? Speech - slurred? Time - is critical, get to hospital asap. 59

Build Threads / Re: Car Hauler Trailer Build« on: September 25, 2017, 11:01:50 AM »

Very good point and advice! Detachable ramps it is!

60

Build Threads / Re: Car Hauler Trailer Build« on: September 22, 2017, 04:17:18 PM »Di you get it painted? Not yet, gotta get stake pockets welded on, and weld the tongue jack. The biggest holdup is deciding what to weld on for ramps. Can't decide if I should go with ones that are basically always attached and flip up, or ones that are detachable and stored under the trailer. 61

Build Threads / Re: Car Hauler Trailer Build« on: September 14, 2017, 04:07:47 PM »

I have 3 5/8" hanger straps now, so I thought it might be worth trying shorter 2 1/4" hanger straps and seeing if that brings the axles away from the frame enough. Barring that I'll put spacers under front, center and rear hangers as you suggested.

62

Build Threads / Re: Car Hauler Trailer Build« on: September 14, 2017, 02:42:41 PM »Might be easier to get new springs with a better arch. I thought about this, but these are the only springs I can get locally without trying to find some online. I thought about the higher equalizer and hangers since the whole suspension is only bolted on finger tight right now, and the hangers are only half welded on currently. 63

Build Threads / Re: Car Hauler Trailer Build« on: September 14, 2017, 07:19:34 AM »

This is what it looks like.

64

Build Threads / Re: Car Hauler Trailer Build« on: September 13, 2017, 09:20:22 PM »

I was just noticing I have less than 2" of clearance between axles and frame. I could do a spring over, but that will raise it more than I'd like or need. I may just get taller front and rear shackles and taller equalizers, it would be good for 1 or 1.5" more clearance, which would be nice.

65

Build Threads / Re: Car Hauler Trailer Build« on: September 12, 2017, 08:11:35 PM »

Got er flipped! Drug it out of the garage. Lifted one side up about 30" with the engine hoist, put a long strap on the top of the trailer and on the loader of the tractor. Once the tractor took the weight off the hoist, I removed it, then pulled it over with the tractor!

Got the springs, axles and wheel on now, so putting it back in the garage should be much easier now!

66

Build Threads / Re: Car Hauler Trailer Build« on: September 11, 2017, 08:42:11 AM »

Well I got the welding done that I can do while the trailer is upside down, so now I have to come up with a clever way to flip this thing over. I'm thinking I may put a dolly under the end of it, and pull it out to the grass with the Kubota, and then just flip it over on the grass. Once it's right Side up I can put the axles/wheels on and then just back it into the garage again.

I thought I might be able to flip it over without removing it from the garage, but that might just lead to disaster and wreck something. 67

Powerplant, Driveline, and Braking / Re: 1993 cummins strong and reliable?« on: August 23, 2017, 04:36:49 PM »

WHat a generous offer! Just go ahead and send that K5 over, and I"ll put the engine in it. Could be a while before I'm ready to send it back though...a long while!!

68

Powerplant, Driveline, and Braking / 1993 cummins strong and reliable?« on: August 23, 2017, 01:10:38 PM »

I'm thinking of getting a 5.9 cummins out of a 1993 Dodge for $700. It's of course the rotary pump, not the inline p-pump that the performance guys seem to like. I'm thinking it will still be ok for me though, as I'm not after a ton of horsepower, I am more looking for simplicity (ie. mechanical diesel) and reliability. Any thoughts on how these engines (with rotary pump) are for reliability ? Would love to put it in an old suburban, but so hard to find a pre-1988 3/4 ton suburban in decent shape around here.

69

Build Threads / Re: Car Hauler Trailer Build« on: August 23, 2017, 01:03:24 PM »

Yeah, I was planning on spraying. I've got a HVLP gun I bought on sale I'm looking to try out.

70

Build Threads / Re: Car Hauler Trailer Build« on: August 23, 2017, 12:20:15 PM »I used the Rust-Oleum brand tractor paint. I gallon should be plenty. Did you spray it on or roll/brush it on? I've talked to some people who used narrow rollers and liked it better than sprayed. 71

Build Threads / Re: Car Hauler Trailer Build« on: August 23, 2017, 07:19:32 AM »What you gonna paint it with? I haven't decided for sure yet to be honest. I'm thinking maybe tractor/implement paint, as my brother works at a New Holland dealership. Still trying to figure out how much paint I need. I'm thinking a gallon would do it? 72

Build Threads / Re: Car Hauler Trailer Build« on: August 22, 2017, 09:33:02 PM »

Got all the cross members welded in now. Hitch mount is welded in place enough so that I can flip the trailer. Just need to weld the cross members the rest of the way around, and the inside of the corners, and along the wrapped tongue. Rounded some sharp corners on the spring mounts and the frame corners as well. After that I can wire and paint the bottom, woohoo!

73

Build Threads / Re: Car Hauler Trailer Build« on: August 19, 2017, 05:58:40 PM »Even though it is heavy, I would try to roll the trailer on its side for the welding. With clean metal, a good V and gravity it will be solid! Yes I agree that's the way to do it for sure. I'd definitely want to weld is partially or brace it or something before I tip it over so that nothing sags or moves out of place. I actually thought I may weld the whole thing on the inside, and then flip it and do the outside (ie. visible) welds horizontally so that they are both strong and look nice. 74

Build Threads / Re: Car Hauler Trailer Build« on: August 19, 2017, 05:48:08 PM »Grind the front vertical edge of the channel so it is parallel with the front of trailer side to side. So basically you will be grinding the channel back so you can see the full thickness (actually a bit more as the channel is on an angle) of the channel next to that formed hitch mount if you are standing in front of the trailer looking at it. Make sense? Yes ok I thought that's what you meant. I had it like that before I did the contouring. I trimmed the front of the tongue so that it was on a flat plane parallel with the front of the trailer. But I'll be sure to grind it as you suggest to make sure I have lots of surface area to weld to. 75

Build Threads / Re: Car Hauler Trailer Build« on: August 19, 2017, 04:07:03 PM »Contour looks good, you may want to grind the front vertical edge of those channels a little more. In doing so you would give yourself a nice area to lay an inside 90 degree weld & fill it in making it look very clean.X2. I got thinking about this more. Do you guys just mean to grind it back more, or do you mean to angle the edges? 76

Build Threads / Re: Car Hauler Trailer Build« on: August 19, 2017, 10:32:17 AM »Contour looks good, you may want to grind the front vertical edge of those channels a little more. In doing so you would give yourself a nice area to lay an inside 90 degree weld & fill it in making it look very clean. Not a bad idea at all, I'll give it a try! 77

Build Threads / Re: Car Hauler Trailer Build« on: August 19, 2017, 09:27:16 AM »

Contoured the tongue this morning, and got things fitted up. I didn't tack it into place, because then the garage door won't close! lol

But I cleaned up the metal and am ready to weld, will just have to try and move everything back a little. I put a bolt in to make sure I didn't get so deep as to not allow the nut to thread on properly.  78

Build Threads / Re: Car Hauler Trailer Build« on: August 18, 2017, 07:40:54 PM »If you weld both outside & inside that channel vertically it won't go anywhere. Only other thing I might do is cut a gusset to lay on top & bottom of a-frame then weld it on. Only would need to be 6" front to rear & if adjustable channel extends above or below then you could add additional vertical gusset to it as well. I will definitely gusset the top half. There will be probably 3 holes above the tongue. I'm hoping if I contour the tongue a little to the round edges sit back into it a little better it will close up those gaps some. 79

Build Threads / Re: Car Hauler Trailer Build« on: August 18, 2017, 07:29:40 PM »

I bolted on the front axle, and measured from front side of tongue to center of opposite axle. Did both sides, and they were exactly (well 1mm or less in the difference) the same. So I welded on the angle piece of the tongue to the frame. I will clean off the frame and wrapped part of the tongue tomorrow and fully weld up what I can while it's still upside down.

I then trimmed the front of the tongue so it's flat. And I'm debating the best way to weld on my hitch mount. I'm thinking either contour it so that it fits nicely. Or weld some plate on and then well the hitch mount to the plate. Any thoughts?

80

Shops Garages and Barns / Re: My first garage!« on: August 17, 2017, 07:28:38 PM »so how did the garage turn out? is it truly complete or odds and ends left to finish? Well I would say it's as complete as it needs to be. I've got the trailer project in there now, and it's been a great spot to keep the kubota etc. I didn't bother painting the walls yet, and concrete is still bare, but that's ok. To be honest we've been thinking of listing out house and buying or building somewhere a little more private, paying off some debts etc. But I'm certainly happy with my garage now as-is. 81

Build Threads / Re: Car Hauler Trailer Build« on: August 17, 2017, 06:06:22 PM »Another one of my dumb questions but you are measuring from hub (front axle) on each side to the front / center of tongue to make sure it pulls straight? Some guys even have the passengers' side a little shorter (1/16 to an 1/8") to help with crown built into most roads. I've never done that for the record but have heard of guys doing it that have built a lot of trailers. I will yes, once I get the axles up on the springs. I'll do a final check of a few things to make sure it's all still square and then sew it up good and solid. I'll then grind off any sharp corners on the bottom and paint the bottom while it's still upside down. 82

Build Threads / Re: Car Hauler Trailer Build« on: August 17, 2017, 05:30:48 PM »Pintle ring is a great addition if you don't want every long lost "friend" trying to borrow your trailer. Gooseneck is even better for this imo.... You know, that had crossed my mind. If I ever get a bigger truck/trailer combo, I'm thinking it'll be a goose neck trailer for sure. Got my tongue bent and tacked on. Each side of the tongue measures the same distance to the front corner of the trailer, and everything seems to be squared up nicely. One side...  The other side...  83

Build Threads / Re: Car Hauler Trailer Build« on: August 17, 2017, 12:35:32 PM »

Laying up the tongue pieces now. Gonna get them in place and centered etc, and then tack them into place. After they are tacked and I have cut the notches I can bend around the ends of the wrapped tongue and weld them into place as well. My angle is a little less than 50 deg, more like 40 or 45, but i think it will be fine, as I'm not using a 50 deg coupler anyway. I'm welding an adjustable coupler, that is basically 12 inches of vertical channel with a bunch of holes in it.

84

Build Threads / Re: Car Hauler Trailer Build« on: August 12, 2017, 12:24:08 PM »Welds look good, if you're not opposed I would fully weld them all the way around. In areas where salt & rust are an issue I think it will make the trailer last longer. If not that's a spot where crap can get in & start deteriorating the joint. If it was a non structural spot I would recommend at very minimum caulk the spots that you didn't weld prior to paint. Yeah that's along the same lines as I was thinking as well. Probably won't need it for strength, but will seal up the little nooks and crannies better. 85

Build Threads / Re: Car Hauler Trailer Build« on: August 12, 2017, 11:38:07 AM »

Just a quick update. welded in the cross members that I cleaned up with the grinder. The welds look pretty good I think, I'm happy with them.

Think there's be any benefit to welding inside the C on the cross members as well, or would web and flange on the outside only be ok? 86

Build Threads / Re: Car Hauler Trailer Build« on: August 07, 2017, 09:02:48 PM »rcampbell, how do you like that compressor? I've never heard of the Omega brand. It's been great! It's a company here in Canada, in Ontario. They do more of the industrial type stuff, but also contractor stuff too. Mine is from the professional series. http://omegacompressors.com/compressors/professional/ Mine is the PK6560V model, which is really more compressor than I need, but not really :) I've been very happy with it for sure. 87

Build Threads / Re: Car Hauler Trailer Build« on: August 06, 2017, 07:18:24 PM »

I knocked off and cleaned up the remaining two thirds of the cross members, mostly to see if the welds would be a little different/better. It actually didn't take much time. I figured I'll have no other better opportunity, and worse case, the welds looks the same, nothing to lose really!

88

Build Threads / Re: Car Hauler Trailer Build« on: August 06, 2017, 01:19:24 PM »You need bare metal, clean it up some. Yeah I know it should be a lot cleaner. Problem is they are all tacked in place. I suppose I could/should pop them off on at a time, clean up, re-tack and then fully weld. Well at least the 8 of 13 that aren't welded yet that is! 89

Build Threads / Re: Car Hauler Trailer Build« on: August 06, 2017, 01:12:19 PM »Penetration looks OK, but shouldn't have the high bead down the center. I think you need a little more heat and clean the weld area better past the coating. I was sorta thinking that as well. Perhaps I'll try bumping up the volts and see what happens. The wire speed is about as fast as I'd want it, and perhaps that's part of the problem too, that I could just be moving the gun along a little faster? I tried a lower wire speed, but it just sounds...well too slow! 90

Build Threads / Re: Car Hauler Trailer Build« on: August 06, 2017, 11:52:21 AM »

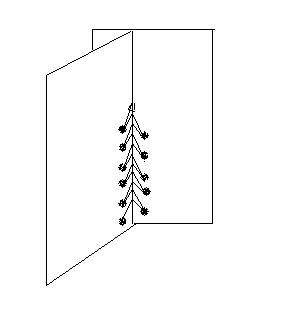

Holding as vertical as I can and doing inverted V, is that the same as texas 2 step?

Here's a diagram of what I'm doing:

91

Build Threads / Re: Car Hauler Trailer Build« on: August 06, 2017, 10:55:49 AM »

I'm so glad I raised this frame off the ground, so nice to be able to sit and weld!

Here's a pic of my vertical up welds, I think they look ok. It's not my favorite weld to do, but much better when I can sit and do it at eye level! Here's two different cross members. Each bead has a little bump in it where I have to run over the existing tack, which was done with flux core wire, but it's not too terrible.

92

Build Threads / Re: Car Hauler Trailer Build« on: August 05, 2017, 06:49:26 AM »

Well, I got tired of trying to see joints I was going to weld with the frame 6" above the floor, so I lifted the ends up with the Kubota, and now it's 38" off the floor!

Should be much nicer on my back too! 93

Build Threads / Re: Car Hauler Trailer Build« on: August 03, 2017, 08:38:13 AM »Those welds look much better than the first couple which were smooth, but didn't seem to have enough added material from the wire feed. (Ken's eyes are old and failing.....reason he loves Hillary is he originally thought she was Bo Derek) I did turn up wire speed ever so slightly, and it still seems quite happy, so will likely leave as it is now. Speaking of welds, I've seen on some fully wrapped tongues, that the sections of the tongue that are parallel to the frame rail (before they bend in to make the tongue) are slightly wider than the trailer frame to give a little ledge to give more material to weld. Or at least that's what I assume it's for. Does that make sense to do that? 94

Build Threads / Re: Car Hauler Trailer Build« on: August 03, 2017, 08:28:57 AM »Yes, those beads weren't the prettiest because they both had a tack midway that I welded over. The welder seems to be running hot enough, a real nice angry sizzle comin out of it, not holes in the welds and smooth and splatter free. Yes, that's a very good suggestion actually. It will indeed be vertical weld, unless I flip it 90 degrees so that the side of the trailer is on the ground, which could be a possibility too I guess. I was planning welding 3 sides, yes. I was going to weld the back of the C now, and then when it's flipped right-side-up was going to weld the bottom flange on the inside of the C and the top flange on the top of the C. I think that should be ok? 95

Build Threads / Re: Car Hauler Trailer Build« on: August 03, 2017, 07:22:35 AM »

Yes, those beads weren't the prettiest because they both had a tack midway that I welded over. The welder seems to be running hot enough, a real nice angry sizzle comin out of it, not holes in the welds and smooth and splatter free.

That's an excellent point about removing sharp edges, wouldn't have thought of that, but it makes complete sense!! Thanks for the tip! 96

Build Threads / Re: To build or not to build« on: August 02, 2017, 09:14:51 PM »Wow. I love you guys(in a non gay kind of way). Math typo. Don't force yourself to get a vehicle from 1983 unless you really want to! :) 97

Build Threads / Re: Car Hauler Trailer Build« on: August 02, 2017, 09:08:14 PM »

Next I will weld the long sides of the cross members (and do the top and bottom of each when I flip it over). Need to clean the ends up the cross members and where they meet the side rail though. Will sort of be a pain in the ass since it's a 90 deg corner on each one. I'm thinking of using a grinding stone or small wire wheel on the die grinder. Any ideas or tips?

98

Build Threads / Re: Car Hauler Trailer Build« on: August 02, 2017, 09:05:14 PM »

Welded on all 6 spring mounts to. Will wait to do the long sides when I flip it over.

99

Build Threads / Re: Car Hauler Trailer Build« on: July 30, 2017, 08:24:57 PM »I think you are fine on the springs too. Those spring do not have a huge arch so I doubt you would see much past vertical with a heavy load. Yeah thats the new angle, i thought it looked better. Just holdin er on with vice grips right now! 100

Build Threads / Re: Car Hauler Trailer Build« on: July 30, 2017, 07:14:09 PM »I think you are fine on the springs too. Those spring do not have a huge arch so I doubt you would see much past vertical with a heavy load. You mean in my latest pic I assume yes? |